History Of Kashmir Carpets

HISTORY OF KASHMIR CARPETS

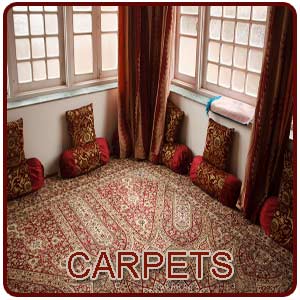

HISTORY OF KASHMIR CARPETSThe Kashmiri Carpets are famous not only in India but across the globe. The Kashmiri Carpet is known for its

specialty of being handmade and similarly it is knotted and not tufted. The History Of Kashmiri Carpets is

nearly 1500 years old and it is not exactly known where and by whom the first Carpet was made. However in India

Carpet weaving was first introduced in Kashmir in late 15th Century by King Budshah who brought artisans from

Persia to train the people in Kashmir to spin and weave Carpets. Though the people of Kashmir were already introduced

to weaving and spinning, the King insisted on them learning the technique from the Persians.

CARPET WEAVING INDUSTRY OF KASHMIR

CARPET WEAVING INDUSTRY OF KASHMIRFactories or locally referred as Karkhana’s were soon started by the King which led to a flourishing industry

in the field of carpet weaving in the valley of Kashmir. But however after the period of King Badshah there

was a major setback in this field only to be revived later during the rule of the Mughal Emperor Jehangir.

It was the great Saint Akhun Mulla Rahnuma of the Mughal period who played a major role in reviving the

Carpet weaving industry with the help of the then Governor of Kashmir during 1600. Once again there was

a dip in the industry at the time of the Afghan and the Sikh rule during which there was a big crisis in all the

field of Craft. The mid of the 18th century witnessed an unexpected growth in the carpet industry with an

increased quality and quantity.

SPECIALTY

SPECIALTYIt was during the mid 18th century that the beautiful mughal Carpets from Kashmir were displayed at

the Crystal Palace exhibition in London and was very much appreciated by the Europeans and slowly

the Kashmiris started to cater according to the need of the Western culture. There was once again a

setback in the Carpet industry at the time of world recession in 1902. Also the partition of India affected

the market for the Carpets both at national and international level. Only during the late 20th century the

local manufacturers took steps in re-establishing this industry and then made a continuous progress. Once

the local government was established in the state during 1950’s there was more effort to stabilize the carpet

industry in order to increase the revenue of the state.

TOURISM AND HANDICRAFTS CENTERS WERE STARTED TO PROMOTE TOURISM

TOURISM AND HANDICRAFTS CENTERS WERE STARTED TO PROMOTE TOURISM

Soon the Tourism and Handicrafts centres were started to promote tourism and the Craft of the State which resulted in great income generation for the Manufacturers and various other steps were taken to promote this on a commercial platform. Slowly the process of carpet weaving was transferred to rural areas as small scale industries and lot of training programs were conducted to work on the betterment of the skills.

Though initially carpet weaving was only the men’s domain, soon official agencies took steps to encourage this among the women which led to a positive development. Large Arkansas was established on a commercial scale generating employment and resulting in the creation of numerous ancillary units which were the prime recipients of subcontracted work.

SPECIALTY OF KASHMIR CARPETS

SPECIALTY OF KASHMIR CARPETSThe making of a Kashmiri carpet is a pure art and its quality depends on the number of knots. It is usually

handmade and hand knotted and is made of pure wool or pure silk whereas a low quality carpet may be a

blend of wool, Cotton and Silk. The Silk Carpet is usually woven with Mulberry Silk and its quality is tested

based on the number of knots it has, for 600-900 knots per square inch ranks a very high quality and durability.

It takes at least 8 to 10 months for weaving of an intricate and a good quality Carpet. The fact of the Kashmiri Carpets

being priced high is quite common for the amount of work and the time it involves. The magic behind the entire process

of carpet weaving involves the entire family or the household sitting around a handloom throughout the day with

dedication and concentration weaving magic with their fingers to convert mere silk or woolen threads into perfect

designs of beautiful colors.

SILK CARPETS ARE VERY LIGHT WHEN COMPARED TO THAT OF THE STAPLE

SILK CARPETS ARE VERY LIGHT WHEN COMPARED TO THAT OF THE STAPLEThe Silk carpets are very light when compared to that of the staple. In spite of great difficulties faced by this

industry at present this traditional heritage is till given life by the weavers by giving immortal contribution

from their side. They not merely weave design from their mind but it is much more than that for they weave

poetry into enchanting designs and everlasting beauty. They weave carpets of different designs like 2×3, 3×5,

4×6, 6×9, 7×10, 8×10, 9×12, 10×14, 12×18, etc. The Kashmiri Carpets are India’s pride. The carpets are

also used as wall hangings and in beddings.

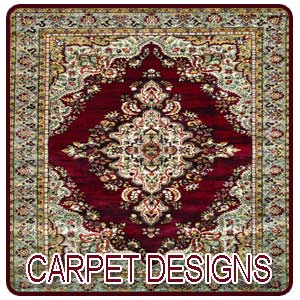

Each Carpet is designed with a symbolic meaning where tree of life is the most common design used and also the designs influence the tradition and the culture of the particular area.

DIFFERENT SOFT COLORS ARE ALSO USED IN THE MANUFACTURE

DIFFERENT SOFT COLORS ARE ALSO USED IN THE MANUFACTUREA parrot refers to life, a sparrow to fertility and good harvest, trees like palm trees, pear trees, and pomegranate

trees represents fulfillment and blessings, Roses signify prosperity. Animals like camel denotes\ wealth and happiness,

a lion represents loyalty, scenes with fighting animals on oriental carpets symbolize the eternal struggle between

good and evil. The peacock, the national bird of India, denotes royalty. Different soft colors are also used in the

manufacture where sky blue denotes Persian national color, green is a religious color for Muslims often used in

prayer rugs, Red represents good virtues like joy and cheerfulness, Indigo blue represents solitude. Black color is

generally avoided.

MAKING OF CARPETS

MAKING OF CARPETSThe art of Carpet weaving in Kashmir is passed from one generation to another and most of these

traditional weavers prefer to hand weave the Carpets in spite of many new mechanized process which

has come up. The process of Kashmiri Carpet making is quite laborious for it involves a lot of time and

different steps starting right from cultivation of silk or wool, treating and dyeing it, deciding the pattern

of the carpet, weaving and then adding the final touches. Nakaash is the person who designs the Carpet,

a Kalimba is the weaver and the ranger is the person who Dyes the Carpet in the local Kashmiri language.

In the making of the Carpet the weaver follows the Talim chart which is a coded colour chart. This chart

indicates the number of knots which has to be weaved according to the panned colours. As the day starts

the master weaver reads out the code and the assistants follows the instructions carefully.

COLORS AND NUMBERS OF KNOTS TO BE WOVEN ARE INDICATED BY SIGNS

COLORS AND NUMBERS OF KNOTS TO BE WOVEN ARE INDICATED BY SIGNS

The colors and numbers of knots to be woven are indicated by signs. The steps carry on as the weaver chants

the Talim and winds the warp around the loom. This is supposed to be a more accurate method than the graphic

method. Once the Carpet takes its shape then it is preceded by the knotting and the carpet is rolled back

to the loom. The final stage in carpet weaving is the washing which adds shine and glimmer. Washing is most

commonly done with soap, bleaching powder and other natural chemicals. The wash is followed by sun drying

and then clipping. The carpet then comes to the finishing stage which needs the hand of skilled artisans and is

done piece by piece in hand knotted carpets. The radiance of the carpet is increased by constant polishing of the

pile with the feet. Nowadays mercerized cotton is used in the production of the carpets and the base is usually

made either from cotton or silk.

KASHMIRI CARPETS – A LIFE TIME INVESTMENT

KASHMIRI CARPETS – A LIFE TIME INVESTMENTThe Kashmiri Carpets can be considered as a life time investment for it is hand-made. It is always prized quite

high for the making of the Carpet is quite laborious and time involving. Also the raw materials used in the

production are very expensive like wool and silk. A handmade Kashmir carpet ranges from anywhere between

Rs. 7000 to Rs. 20,00,000 depending upon the workmanship and the material used.

However nowadays the prices are curbed for the fact that the artisans these days use mercerized cotton in the

making of the Carpet. Also various other unique features add to the heavy pricing of the carpet. The latest trend

used in the making of the carpet is the use of mercerized cotton. However the use of computer for designing by

Indian Institute of Carpet Technology ( IICT ) on software called Naqash is getting quite common for it is said to

save the time and money of the artisans.

INNOVATIONS LIKE “PSEUDO-NEW” DESIGNS AND SOME QUALITY CONTROL STEPS

INNOVATIONS LIKE “PSEUDO-NEW” DESIGNS AND SOME QUALITY CONTROL STEPSThe “Miras Carpet Industries” has come up with eight centers in different parts of Kashmir to impart training

to the people in the field of carpet weaving.

Thus now the artisans are trying to use different kinds of fabrics incarpet weaving. Innovations like “pseudo-new”

designs and some quality control steps which are followed has helped in the enhancement of the industry.

In spite of innumerable specialties and durability both the art and the artisans have suffered and are suffering a lot

due to the fading of the art in various grounds like financial resources, lack of modern technology in dyeing and

designing, production of duplicate Kashmiri carpets, etc.

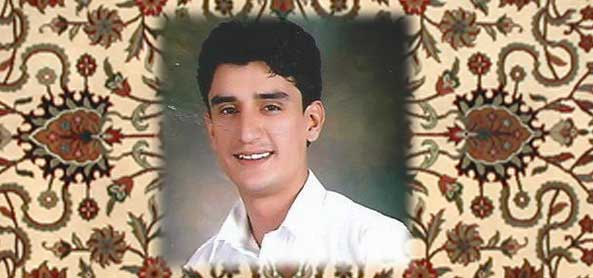

GH. MOHMMAD GANI who is known to be weaving the most Expensive Carpets in Kashmir says that inspite

of the excellent tourism of the state the survival is becoming quite difficult for the weavers mainly because of

economic inflation.

WEAVING IS PRACTICED MORE IN RURAL AREAS OF KASHMIR

WEAVING IS PRACTICED MORE IN RURAL AREAS OF KASHMIRHe complaints that it is difficult to work with Silk thread and cotton after the sunset for the electricity is very erratic. This art of weaving is practiced more in rural areas of Kashmir like Baramulla and Budgam etc districts. Apart from these places there are few colonies in and around Dal Lake and Achar Lake in Srinagar city where many artisans are associated with the weaving. However the showroom people who have shops in urban areas though they purchase at a low price they are able to sell it at exorbitant rates. So the sufferers are mostly the makers who live in the rural areas. This industry is roughly said to bring a turnover of about 650 crores strong with a majority of products worth Rs 412.45 crores exported to United States, Germany, France, United Kingdom and Gulf countries.

Saffron Kesar

Saffron Kesar